Because of its exceptional formability, copper can be formed as desired at the job site. Copper tube, properly bent, will not collapse on the outside of the bend and will not buckle on the inside of the bend. Tests demonstrate that the bursting strength of a bent copper tube can actually be greater than it was before bending.

Because copper is readily formed, expansion loops and other bends necessary in an assembly are quickly and simply made if the proper method and equipment are used. Simple hand tools employing mandrels, dies, forms and fillers, or power-operated bending machines can be used.

Both annealed tube and hard drawn tube can be bent with the appropriate hand benders. The proper size of bender for each size tube must be used. For a guide to typical bend radii, see Table 4.1.

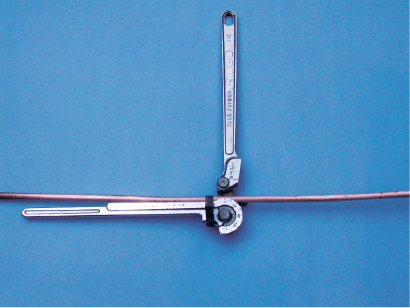

The procedure for bending copper tube with a lever-type hand bender is illustrated in Figure 4.1 below.

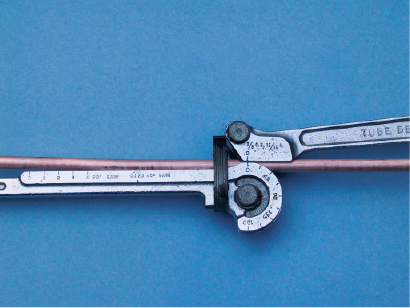

Figure 4.1. Bending Using a Lever-Type Hand Bender (tool shown is appropriate for use with annealed tube only)

(A) With the handles of the tube bender at 90 degrees insert the tube into the forming wheel groove with the mark for the center-of-bend aligned with the "0" on the forming handle. Engage the tube holding clip to secure the tube to the bender at the appropriate location for bending.

(A) With the handles of the tube bender at 90 degrees insert the tube into the forming wheel groove with the mark for the center-of-bend aligned with the "0" on the forming handle. Engage the tube holding clip to secure the tube to the bender at the appropriate location for bending. (B) Rotate the handle to the position shown. The "0" on the handle must align with the "0" on the forming wheel before any bend pressure is applied to the bending handle. Apply gentle but steady pressure on the handle and rotate it to the appropriate degree marking on the forming wheel for the desired degree of bend.

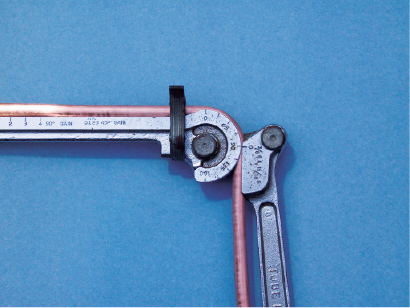

(B) Rotate the handle to the position shown. The "0" on the handle must align with the "0" on the forming wheel before any bend pressure is applied to the bending handle. Apply gentle but steady pressure on the handle and rotate it to the appropriate degree marking on the forming wheel for the desired degree of bend. (C) Once the appropriate degree of bend is reached, as identified by the degree mark on the forming wheel, the bend is completed. The properly bent tube can be removed from the bender by rotating the handle back to the 90 degree position as shown in (A), disengage the holding clip and remove the tube from the bender.

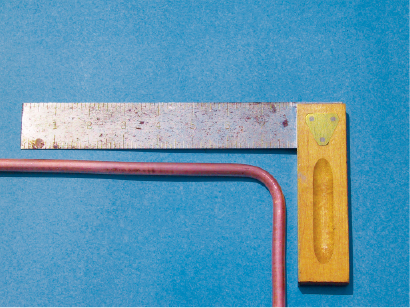

(C) Once the appropriate degree of bend is reached, as identified by the degree mark on the forming wheel, the bend is completed. The properly bent tube can be removed from the bender by rotating the handle back to the 90 degree position as shown in (A), disengage the holding clip and remove the tube from the bender. (D) To ensure the proper degree of desired bend has been fabricated the bend should be checked against a square or other appropriate tool. (A square is shown here confirming the 90 degree bend.)

(D) To ensure the proper degree of desired bend has been fabricated the bend should be checked against a square or other appropriate tool. (A square is shown here confirming the 90 degree bend.)The tool illustrated is just one of many available to the industry. Of course, if the manufacturer of the tube bender has special instructions regarding his product, such instructions should be followed.

Bending Copper Tube